What is the PDCA Cycle?

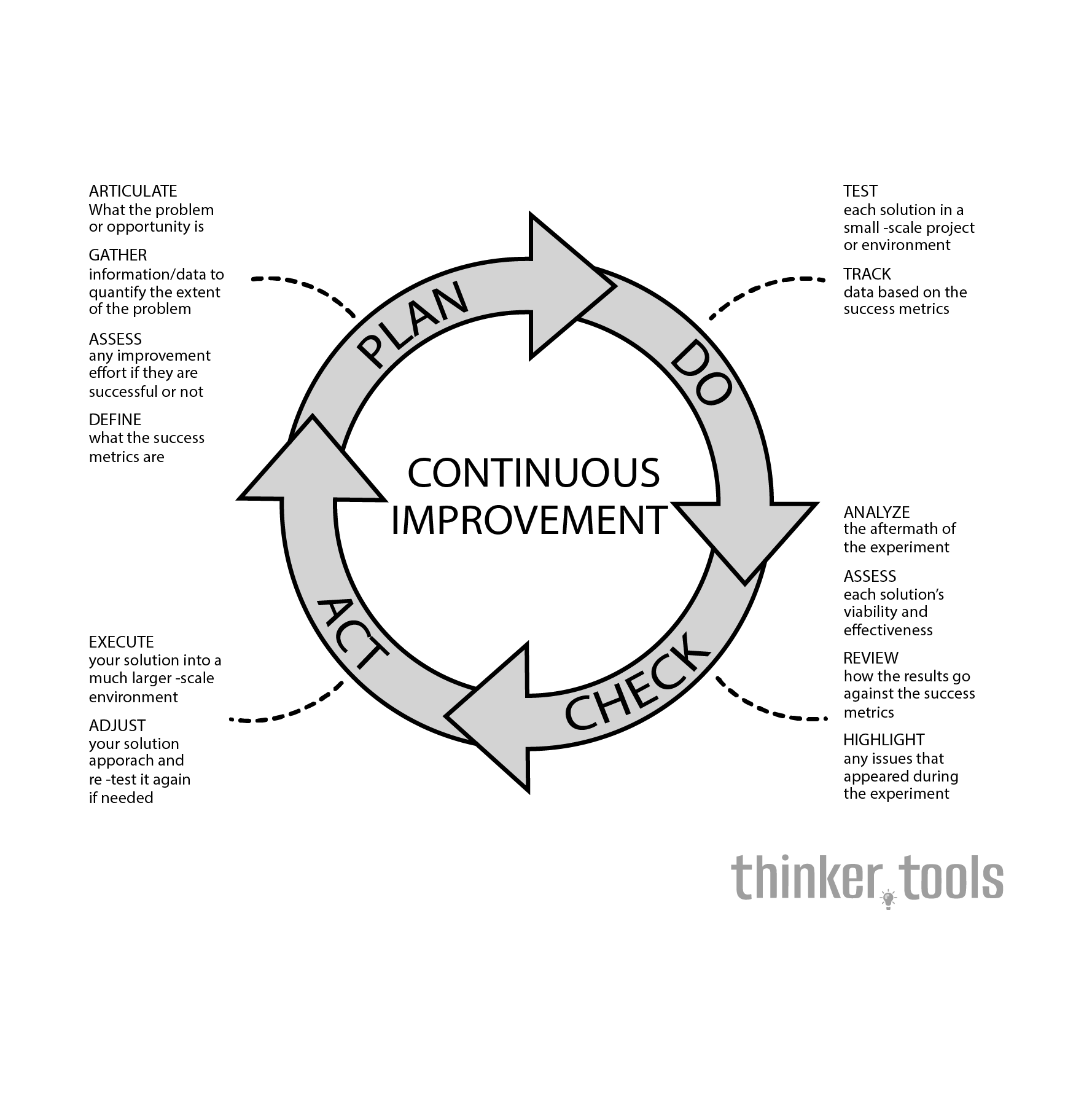

The PDCA Cycle - Plan, Do, Check, Act - is a four-step iterative method for continuous improvement of processes, products, and services. Also known as the Deming Cycle or Shewhart Cycle, it provides a simple yet powerful framework for testing changes, learning from results, and implementing improvements systematically.

Think of PDCA as the scientific method applied to business and life. Rather than making changes based on hunches or implementing massive overhauls that might fail, PDCA encourages small, tested improvements that compound over time. It's the engine that powers everything from manufacturing quality to personal development.

The History and Origin

The PDCA cycle has a fascinating history rooted in the scientific method. Walter Shewhart, a physicist and engineer at Bell Laboratories, first described the concept in the 1920s as a three-step process: specification, production, and inspection.

W. Edwards Deming, Shewhart's colleague and mentee, modified and popularized the cycle in the 1950s, particularly during his work helping rebuild Japanese industry after World War II. Deming's version - Plan, Do, Study, Act (PDSA) - emphasized learning over inspection. The Japanese embraced this methodology so thoroughly that they often call it the "Deming Wheel."

The framework became central to the Total Quality Management (TQM) movement and later influenced Lean Manufacturing, Six Sigma, and Agile methodologies. Today, PDCA is used worldwide across industries as diverse as healthcare, software development, education, and personal productivity.

How to Use PDCA Step by Step

Plan: Design the Change

The Plan phase is where you identify an opportunity and plan for change.

Key activities:

- Define the problem or opportunity

- Analyze the current situation

- Set measurable objectives

- Develop hypotheses about what changes might improve the process

- Design the change or test

- Identify success metrics

Questions to answer:

- What are we trying to accomplish?

- What data do we need?

- What are our predictions?

- How will we measure success?

Tools to use:

- Root cause analysis (5 Whys, Fishbone Diagram)

- Process mapping

- Data collection plans

- SMART goals

Do: Implement the Change

Execute the plan, preferably on a small scale first.

Key activities:

- Implement the planned change

- Document problems and unexpected observations

- Collect data systematically

- Train those involved in the change

Best practices:

- Start with a pilot or small-scale test

- Communicate clearly with all stakeholders

- Document everything, including deviations from the plan

- Remain objective about results

Check: Study the Results

Analyze the data and results to determine if the change was successful.

Key activities:

- Compare results to predictions

- Analyze data for trends and insights

- Identify what worked and what didn't

- Document lessons learned

- Determine if objectives were met

Analysis methods:

- Statistical analysis

- Before/after comparisons

- Trend analysis

- Stakeholder feedback

Critical questions:

- Did the change achieve desired results?

- What unexpected outcomes occurred?

- What did we learn?

- Should we adopt, adapt, or abandon the change?

Act: Standardize or Adjust

Based on what you learned, take appropriate action.

If successful:

- Standardize the improvement

- Document new procedures

- Train all relevant personnel

- Implement change across broader scope

- Monitor to ensure sustainability

If unsuccessful:

- Understand why it didn't work

- Modify the plan based on learnings

- Begin a new PDCA cycle

- Consider alternative approaches

Always:

- Document learnings for future reference

- Identify next improvement opportunity

- Celebrate progress and recognize contributors

Practical Examples

Example 1: Restaurant Kitchen Efficiency

Situation: Restaurant experiencing slow dinner service

Plan:

- Problem: Orders taking 25 minutes average (target: 15)

- Hypothesis: Reorganizing prep stations will reduce time

- Metric: Average order completion time

Do:

- Rearrange one station for one week

- Track times for orders from that station

- Document challenges and observations

Check:

- New station averaging 17 minutes (32% improvement)

- Some confusion initially, then rapid improvement

- Staff reports less movement required

Act:

- Implement new layout for all stations

- Create standard work instructions

- Train all staff on new arrangement

- Monitor for sustained improvement

Example 2: Personal Productivity

Situation: Struggling to maintain exercise routine

Plan:

- Problem: Only exercising 1-2 times per week (goal: 4)

- Hypothesis: Morning workouts will be more consistent

- Metric: Weekly workout completion

Do:

- Set alarm 30 minutes earlier

- Lay out clothes night before

- Track workouts for one month

Check:

- Completed 3.5 workouts per week average

- Missed workouts mainly on Mondays

- Energy levels higher on workout days

Act:

- Maintain morning routine

- Add Sunday prep for Monday workout

- Try 2-week PDCA cycle for further optimization

Example 3: Software Development

Situation: High bug rate in production releases

Plan:

- Problem: 15 bugs per release average (target: <5)

- Hypothesis: Code review checklist will catch more issues

- Metric: Bugs found in production

Do:

- Implement checklist for next sprint

- All code reviews must complete checklist

- Track bugs and their categories

Check:

- Bugs reduced to 8 per release

- Most prevented bugs were edge cases

- Review time increased by 15 minutes average

Act:

- Standardize checklist use

- Add automated tests for common edge cases

- Share learnings with other teams

- Plan next PDCA for remaining bug categories

Benefits and Life Improvements

1. Systematic Problem-Solving PDCA provides structure to improvement efforts, preventing random changes and ensuring learning from every attempt.

2. Risk Reduction Testing changes on small scale minimizes risk while maximizing learning opportunities.

3. Data-Driven Decisions Emphasis on measurement and analysis replaces gut feelings with objective evidence.

4. Continuous Learning Culture Regular cycles create organizational learning and adaptation capabilities.

5. Employee Engagement Involving people in improvement processes increases ownership and job satisfaction.

6. Incremental Progress Small, continuous improvements compound into significant transformations over time.

7. Adaptability Built-in feedback loops help organizations respond quickly to changing conditions.

8. Quality Improvement Systematic approach to reducing defects and improving outputs.

9. Cost Reduction Efficient processes and reduced waste lead to lower operational costs.

10. Innovation Enablement Safe framework for testing new ideas encourages experimentation.

PDCA Variations and Related Concepts

PDSA (Plan-Do-Study-Act) Deming's preferred version emphasizing study over check

OPDCA (Observe-Plan-Do-Check-Act) Adds observation phase for better current state understanding

DMAIC (Define-Measure-Analyze-Improve-Control) Six Sigma's expanded version for complex problems

Build-Measure-Learn Lean Startup's adaptation for product development

Common Mistakes to Avoid

- Skipping the planning phase

- Making changes too large to measure effectively

- Failing to collect baseline data

- Not involving the people who do the work

- Abandoning cycles when immediate results aren't seen

- Forgetting to standardize successful improvements

- Not documenting learnings for future reference

Conclusion

The PDCA Cycle is more than a business tool - it's a philosophy of continuous improvement applicable to every aspect of life. By embracing the discipline of planning changes, testing them systematically, learning from results, and acting on that knowledge, we create an upward spiral of improvement.

In a world that demands constant adaptation, PDCA provides the framework for thoughtful, effective change. Whether you're improving a manufacturing process, developing better software, or working on personal goals, the cycle offers a proven path forward.

The beauty of PDCA lies in its simplicity and universality. Four steps, endlessly repeated, can transform mediocrity into excellence. Start small, learn continuously, and watch as tiny improvements compound into remarkable results. That's the power of the PDCA Cycle - turning the wheel of progress, one thoughtful iteration at a time.